Understanding Motor Cooling Fans and Their Advantages

Motor cooling fans play a crucial role in maintaining optimal temperatures for engines and machinery. You find these fans essential in both industrial and automotive settings. They help prevent overheating, ensuring efficiency and longevity. In industrial environments, durable fans cool equipment and personnel, reducing stress in high-temperature areas. Meanwhile, in vehicles, electric fans offer precise control, enhancing engine performance and reducing energy consumption. Understanding these fans' functions and benefits can significantly impact your approach to managing heat in various applications.

What Are Motor Cooling Fans?

Definition and Purpose

Motor cooling fans are essential components in various systems, designed to regulate temperature and prevent overheating. You will find these fans in engines, industrial machinery, and electronic devices. Their primary function is to circulate air, which helps dissipate heat generated during operation. By maintaining a stable temperature, motor cooling fans ensure that equipment runs efficiently and lasts longer.

Basic Functionality

The basic functionality of a motor cooling fan involves moving air across a surface to remove excess heat. You can think of it as a simple yet effective way to manage heat. The fan blades rotate, creating airflow that carries heat away from the motor or engine. This process prevents the buildup of heat, which could otherwise lead to damage or reduced performance.

Importance in Heat Management

Heat management is crucial in any system that generates heat during operation. Without proper cooling, motors and engines can overheat, leading to failures or costly repairs. Motor cooling fans play a vital role in this process by ensuring that temperatures remain within safe limits. In industrial settings, these fans help maintain a comfortable environment for workers and protect sensitive equipment from heat damage. In automotive applications, they keep engines running smoothly and efficiently.

Historical Development

The development of motor cooling fans has evolved significantly over time. Initially, fans were simple mechanical devices with limited capabilities. However, advancements in technology have led to more efficient and effective designs.

Evolution Over Time

Over the years, motor cooling fans have undergone numerous changes. Early models were often bulky and inefficient, but modern fans are lightweight and highly effective. Manufacturers now use advanced materials and designs to improve performance and reduce energy consumption. For example, the use of lightweight materials and aerodynamic designs has enhanced the efficiency of these fans.

Technological Advancements

Technological advancements have played a significant role in the evolution of motor cooling fans. Today, you can find fans with variable speed controls and sensor integration, allowing for precise temperature regulation. These innovations have made it possible to tailor cooling solutions to specific needs, whether in industrial machinery or automotive engines. Electric cooling fans, in particular, have become popular due to their ability to provide consistent airflow and reduce energy usage.

Components of Motor Cooling Fans

Key Parts

Motor cooling fans consist of several essential components that work together to regulate temperature effectively. Understanding these parts helps you appreciate how these fans function.

Blades

The blades are crucial for creating airflow. They rotate to move air across surfaces, dissipating heat efficiently. Manufacturers design blades to minimize air resistance and noise while maximizing airflow. This ensures optimal performance in both industrial and automotive applications.

Motors

The motor powers the fan blades. It converts electrical energy into mechanical energy, enabling the blades to spin. A reliable motor ensures consistent airflow, which is vital for maintaining the right temperature. In modern designs, motors often include features like variable speed controls for precise temperature management.

Housings

Housings encase the motor and blades, providing protection and structural support. They also help direct airflow in the desired direction. Durable housings are essential, especially in industrial settings where fans operate under harsh conditions. High-quality housings contribute to the longevity and efficiency of the fan.

Material Considerations

When selecting motor cooling fans, material choice plays a significant role in performance and durability.

Metal vs. Plastic

Fans can be made from metal or plastic. Metal fans are typically more durable and can withstand higher temperatures, making them suitable for industrial environments. Plastic fans, on the other hand, are lighter and often more cost-effective. They are ideal for applications where weight and cost are critical factors.

Durability and Efficiency

Durability ensures that the fan can withstand continuous operation without frequent maintenance. Efficient fans consume less energy, reducing operational costs. Manufacturers focus on sustainability by using materials that enhance both durability and efficiency. This approach not only benefits the environment but also provides long-term cost savings for users.

Types of Motor Cooling Fans

Axial Fans

Characteristics

Axial fans move air parallel to the fan's axis. This design allows them to deliver high-volume, low-pressure airflow. You will find these fans efficient and requiring less power to operate. Their blades, housing, and suction nozzle contribute to their capacity for air movement.

Common Uses

Axial fans are ideal for applications needing even air distribution. You often see them in cooling machinery and ventilating defined areas. Their efficiency makes them popular in both industrial and automotive settings.

Centrifugal Fans

Characteristics

Centrifugal fans direct airflow perpendicular to the air intake. They produce low-volume, high-pressure airflow. These fans consume more power and generate more noise compared to axial fans. Their design includes a scroll-shaped housing that enhances pressure.

Common Uses

You typically use centrifugal fans in situations requiring high-pressure airflow. They are common in HVAC systems and industrial processes where precise air control is necessary. Their robust design suits demanding environments.

Mixed Flow Fans

Characteristics

Mixed flow fans combine features of both axial and centrifugal fans. They offer a balance between high-volume and high-pressure airflow. You will notice their ability to provide efficient airflow with moderate power consumption.

Common Uses

Mixed flow fans are versatile. You can use them in applications where both volume and pressure are important. They are suitable for ventilation systems and cooling applications that require flexibility in performance.

How Motor Cooling Fans Work

Understanding how a motor cooling fan operates can help you appreciate its role in maintaining optimal temperatures. These fans are designed to manage airflow and dissipate heat effectively.

Mechanism of Action

Airflow Dynamics

A motor cooling fan creates airflow by rotating its blades. This movement draws cooler air into the system and pushes warmer air out. The fan's design ensures that air moves efficiently across surfaces, carrying away excess heat. You will notice that the speed and angle of the blades influence the volume and direction of airflow. This dynamic process helps maintain a stable temperature, preventing overheating.

Heat Dissipation Process

The heat dissipation process involves transferring heat from the motor or engine to the surrounding air. As the motor cooling fan circulates air, it absorbs heat from the motor's surface. This heated air is then expelled, allowing cooler air to take its place. This continuous cycle ensures that the motor remains within a safe operating temperature range. By understanding this process, you can see how crucial these fans are in protecting motors from heat damage.

Integration with Motor Systems

Installation Considerations

When integrating a motor cooling fan into a system, you must consider several factors. Proper installation ensures that the fan operates efficiently. You should ensure that the fan is securely mounted and aligned with the motor. This alignment maximizes airflow and minimizes resistance. Additionally, you need to check that the fan's power supply matches the system's requirements. This step prevents electrical issues and ensures consistent performance.

Compatibility Issues

Compatibility is key when selecting a motor cooling fan for your system. You must choose a fan that fits the motor's specifications. This includes considering the fan's size, power rating, and airflow capacity. Incompatible fans can lead to reduced efficiency or even damage to the motor. By selecting the right fan, you ensure that your system operates smoothly and efficiently. Understanding these compatibility issues helps you make informed decisions when integrating motor cooling fans into your applications.

Advantages of Using Motor Cooling Fans

Performance Enhancement

Increased Efficiency

Motor cooling fans significantly boost efficiency. By maintaining optimal temperatures, these fans ensure that engines and machinery operate smoothly. You will notice improved performance as the fan prevents overheating, which can slow down operations. Technological advancements in cooling fans have led to more efficient designs, enhancing thermal management systems.

Prolonged Motor Life

Cooling fans extend the lifespan of motors. By regulating temperature, they reduce wear and tear on components. This protection minimizes the risk of damage and costly repairs. You benefit from a longer-lasting motor, which means fewer replacements and less downtime.

Cost Benefits

Energy Savings

Using motor cooling fans leads to substantial energy savings. Efficient fans consume less power while providing effective cooling. This reduction in energy usage translates to lower utility bills. You can optimize your energy consumption by choosing fans with advanced features like variable speed controls.

Reduced Maintenance Costs

Cooling fans help cut down on maintenance expenses. By preventing overheating, they reduce the likelihood of mechanical failures. You spend less on repairs and replacements. Regular maintenance becomes simpler and less frequent, saving you time and money in the long run.

Applications of Motor Cooling Fans

Motor cooling fans serve a variety of purposes across different sectors. Their ability to regulate temperature makes them indispensable in many applications. Let's explore how these fans are utilized in various fields.

Industrial Uses

In industrial settings, motor cooling fans play a vital role in maintaining optimal working conditions.

Manufacturing

In manufacturing, you rely on motor cooling fans to keep machinery running smoothly. These fans prevent overheating, which can lead to costly downtime. By ensuring that equipment operates within safe temperature ranges, you enhance productivity and reduce the risk of damage. Industrial Cooling Fans are often constructed from durable materials, making them suitable for harsh environments. They help cool both personnel and equipment, alleviating stress in high-temperature areas.

Heavy Machinery

Heavy machinery generates significant heat during operation. You use motor cooling fans to dissipate this heat effectively. By doing so, you protect the machinery from overheating and extend its lifespan. These fans are crucial in industries like construction and mining, where equipment operates under demanding conditions. The robust design of these fans ensures they can handle the rigors of heavy-duty applications.

Automotive Uses

In the automotive industry, motor cooling fans are essential for vehicle performance and safety.

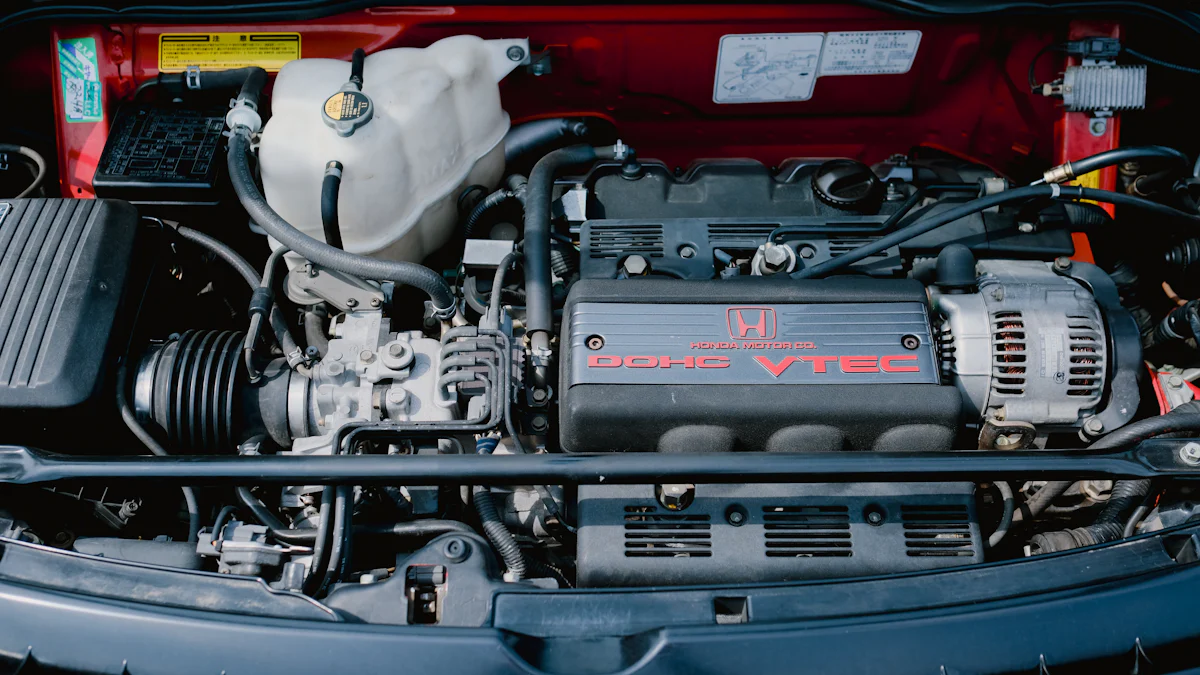

Engine Cooling

Engine cooling fans are critical components in vehicles. They help maintain the engine's temperature, preventing overheating and enhancing performance. By using these fans, you ensure that the engine operates efficiently, even under high-stress conditions. Manufacturers leverage advanced technologies to meet the evolving demands of the automotive industry, ensuring that engines remain within optimal temperature ranges.

HVAC Systems

In automotive HVAC systems, motor cooling fans provide effective air circulation. They help maintain a comfortable cabin temperature by regulating airflow. You benefit from improved air conditioning performance, especially during idle times when cooling is most needed. These fans contribute to a pleasant driving experience by ensuring that the vehicle's interior remains cool and comfortable.

Electronics Cooling

Motor cooling fans are also crucial in the electronics sector, where heat management is vital for device performance.

Computer Systems

In computer systems, you use motor cooling fans to prevent overheating of components like CPUs and GPUs. These fans ensure that the system runs smoothly, reducing the risk of thermal throttling and hardware failure. By maintaining optimal temperatures, you enhance the performance and longevity of your computer. Efficient cooling fans are essential for high-performance computing tasks, such as gaming and video editing.

Consumer Electronics

Consumer electronics, such as gaming consoles and home entertainment systems, generate heat during operation. You rely on motor cooling fans to dissipate this heat, ensuring that devices function properly. By using these fans, you prevent overheating, which can lead to reduced performance or even permanent damage. Effective cooling solutions are crucial for maintaining the reliability and efficiency of consumer electronics.

Challenges and Considerations

Common Issues

Motor cooling fans, while essential, can present some challenges. Understanding these issues helps you maintain optimal performance.

Noise Levels

You might notice that cooling fans can produce significant noise. This often results from broken fan blades, a worn motor, or a damaged fan clutch. Many choose to replace the entire fan assembly to resolve this. Alternatively, changing the blade assembly, clutch, or motor can also correct the noise problem.

Wear and Tear

Over time, cooling fans experience wear and tear. This can lead to intermittent operation, causing occasional overheating. Issues like defective control modules, loose connectors, or faulty sensors often contribute to this. Checking sensors with a digital multimeter and using a diagnostic scanner for control modules can help identify problems. Replacing damaged parts ensures the fan functions properly.

Selection Criteria

Choosing the right motor cooling fan involves careful consideration of several factors.

Size and Capacity

Selecting a fan with the appropriate size and capacity is crucial. You need to match the fan to your system's specifications. An incompatible fan can reduce efficiency or even damage the motor. Ensuring the fan fits your needs guarantees smooth operation.

Environmental Factors

Environmental conditions also play a role in fan selection. Consider the temperature and humidity levels where the fan will operate. Fans made from durable materials withstand harsh conditions better. By taking these factors into account, you ensure the fan performs reliably in its intended environment.

Future Trends in Motor Cooling Fans

Technological Innovations

Smart Fans

You will see smart fans becoming more prevalent in the motor cooling industry. These fans integrate sensors and advanced controls to optimize performance. By adjusting speed and airflow based on real-time data, smart fans enhance cooling efficiency. This technology allows you to maintain optimal temperatures with minimal energy use. The integration of smart technology also enables remote monitoring and diagnostics, providing you with greater control and insights into fan operations.

Energy Efficiency Improvements

Energy efficiency remains a key focus in the development of motor cooling fans. Manufacturers are designing fans with aerodynamically efficient blades and lightweight materials. These advancements reduce energy consumption while maintaining effective cooling. Variable speed fans adjust their operation based on demand, further enhancing efficiency. By choosing energy-efficient fans, you contribute to sustainability and reduce operational costs.

Market Growth

Industry Projections

The motor cooling fan market is poised for significant growth. As industries prioritize energy efficiency and performance, the demand for advanced cooling solutions increases. You can expect innovations in design and technology to drive this growth. The adoption of electric cooling fans in automotive and industrial applications will also contribute to market expansion. These trends indicate a promising future for the industry.

Emerging Markets

Emerging markets present new opportunities for motor cooling fans. As developing regions industrialize, the need for efficient cooling solutions grows. You will find increased demand in sectors like manufacturing, automotive, and electronics. By tapping into these markets, manufacturers can expand their reach and influence. This growth not only benefits the industry but also supports global efforts toward sustainable development.

Motor cooling fans are essential in maintaining optimal temperatures across various applications. You’ve learned how these fans enhance performance and efficiency in both automotive and industrial settings. By preventing overheating, they ensure engines and machinery operate smoothly. In industrial environments, motor cooling fans alleviate stress on workers by cooling equipment and personnel. As technology advances, you can expect even more efficient designs and smart features. Embracing these innovations will help you manage heat effectively, ensuring longevity and reliability in your systems.

Brand Introduction: X-HON Fans

At X-HON Fans, we are a seasoned manufacturer with a focus on the production of cooling fans. Our products are widely recognized and utilized in a variety of industries, including lighting, wine cabinets, automotive cooling systems, welding machinery, and beyond. We specialize in the manufacturing of DC brushless fans, AC fans, dustproof guards, compact cooling fans, and industrial fans. We have achieved ISO9001 international quality system certification, and our products have been endorsed by certifications such as ROHS, TUV CE, FCC, SGS, and UL test reports. Our fans are integral to the operations of computers, communication devices, consumer electronics, automotive electronics, HVAC systems, and building automation.

We are committed to the production of high-performance cooling fans, providing both standard and tailored solutions to meet the specific needs of our clients. We offer sample testing to ensure that our products meet the highest standards of quality and reliability. Additionally, we are now pleased to provide IP68-rated waterproof fans across our entire product line, catering to the efficient and stable cooling requirements in complex environments.

See Also

Optimal Selection of Electric Cooling Fan Models

Discovering Top Evaporative Cooling Fan Manufacturers

Comprehensive Overview of the Finest Cooling Fans in 2024

Effective Cooling Fan Solutions for Personal Computers

Tranquil Workspace Tips: Selecting Noiseless Cooling Fans

See Also

Exploring the Advantages of Different Cooling Fans

Effective Cooling Solutions for Personal Computers

Pros and Cons of Water-Cooled Fan Systems

Unexpected Methods for Efficient Industrial Cooling

The Popularity of Axial Fans in Product Cooling Applications

About US

X-HON

X- HON is a leading manufacturer of cooling fans,speciaizing in research, development, and production forover a decade. With a focus on quaity and inovation, we ofer arange of cooling solutions to global markets, ensuring superior performance and reliable service.

Address

Address1: HuaYuan Building, Xixiang Avenue, Bao'anDistrict, Shenzhen, Guangdong Province, china;

Address2: DaLingShan District, DongGuan,Guangdong Province, china

Contacts

frelin.jiang@x-hon.com

bella.cai@x-hon.com

+86 15626528321

To inquire about product specifications or to request custom fan designs,

please leave your email address.

Our dedicated service team will be in contact with you shortly.