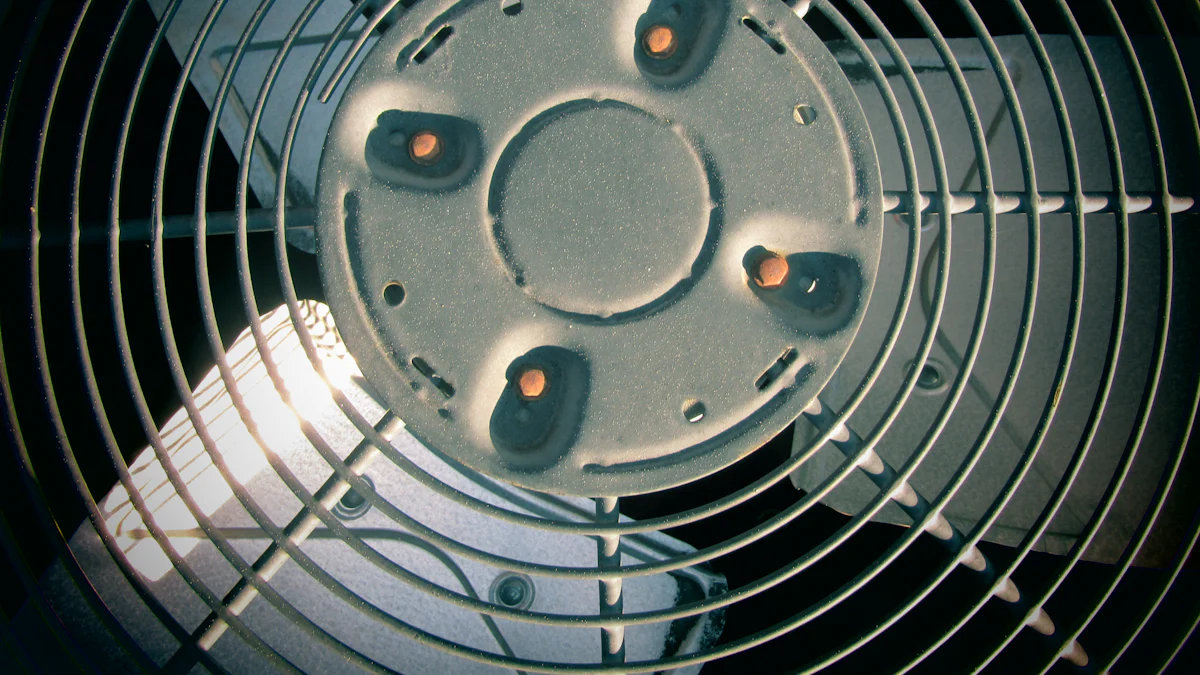

Industry Fan Review: Power and Efficiency Unveiled

High-velocity fans play a crucial role in industrial settings. These fans enhance airflow and maintain optimal working conditions. The review aims to explore the power and efficiency of industry fans. Selecting the right fan impacts energy consumption and operational costs. Fans with lower energy use offer benefits like quieter operation and reliability. The Fan Energy Index (FEI) helps in choosing efficient models. Industrial fans also contribute to safety by maintaining air quality. Understanding these aspects sets the context for a detailed discussion on industry fan performance.

Key Features of High-Velocity Industrial Fans

Heavy-Duty Construction

High-velocity industry fans boast robust construction. Manufacturers use durable materials to ensure longevity. Steel and aluminum often form the framework. These materials resist wear and tear in harsh environments. The design of these fans considers both functionality and aesthetics. Engineers focus on creating efficient airflow paths. This approach minimizes resistance and maximizes performance.

Adjustable Speed Settings

Adjustable speed settings offer flexibility in industry fan operations. Speed control mechanisms allow users to tailor airflow to specific needs. Dial controls or digital interfaces provide easy adjustments. Variable speeds benefit different industrial applications. Lower speeds suit gentle ventilation tasks. Higher speeds tackle demanding cooling requirements. This versatility enhances the fan's utility across various settings.

Energy Efficiency

Energy efficiency remains a crucial aspect of industry fan design. Modern fans incorporate energy-saving technologies. These innovations reduce electricity consumption significantly. The Fan Energy Index (FEI) serves as a valuable tool. FEI helps users select the most efficient fan models. Efficient fans lower operational costs by reducing energy usage. A more efficient fan may cost slightly more initially. However, the savings quickly offset the initial investment. This results in a shorter payback period.

Product Information:

SD5V Industrial Fan features a variable speed setting. This allows adjustments for different seasons. Users can stir warmer air in winter or minimize floor sweating. The fan's design ensures optimal airflow over large areas.

Fan Energy Index (FEI) Efficiency research highlights significant energy savings. Selecting fans with high FEI ratings reduces energy costs. Efficient fans also offer quieter and more reliable operation.

Applications and Benefits of Industry Fans

Cooling and Ventilation

Industrial fans play a vital role in cooling and ventilation. High-velocity fans distribute heat effectively in large spaces. These fans enhance air destratification by mixing warm and cool air layers. This process maintains consistent temperatures throughout the workspace. Industrial fans also improve ventilation by circulating fresh air. Proper airflow reduces humidity and eliminates stagnant air. Workers experience increased comfort and productivity as a result.

Industrial Cooling Solutions

Industry fans provide efficient cooling solutions. These fans target specific areas that require temperature control. High-velocity fans deliver powerful airflow to cool machinery and equipment. This targeted approach prevents overheating and extends equipment lifespan. Industrial fans also support HVAC systems by reducing their workload. This collaboration leads to energy savings and lower operational costs.

Enhancing Airflow in Workspaces

Enhanced airflow in workspaces offers numerous benefits. Industry fans circulate air to remove pollutants and odors. This circulation improves indoor air quality and creates a healthier environment. Fans also help in maintaining optimal working conditions by reducing heat stress. Employees benefit from improved comfort and reduced fatigue.

Drying Capabilities

Industry fans excel in drying capabilities. These fans facilitate the evaporation of water on surfaces. Rapid drying prevents moisture-related issues such as mold growth. Industrial fans also expedite the drying of paints and coatings. This acceleration enhances production efficiency in manufacturing processes.

Effective Moisture Removal

Effective moisture removal is crucial in industrial settings. Industry fans quickly eliminate excess moisture from floors and equipment. This removal reduces the risk of accidents caused by slippery surfaces. Fans also combat sweating slab syndrome by keeping floors dry. This prevention ensures safety and maintains operational efficiency.

Use in Manufacturing Processes

Manufacturing processes benefit from the drying capabilities of industry fans. These fans speed up the drying of adhesives and sealants. Faster drying times increase production rates and reduce downtime. Industry fans also assist in curing processes by providing consistent airflow. This assistance ensures uniform drying and high-quality finished products.

Quiet Operation

Quiet operation is an essential feature of modern industry fans. Noise reduction technologies minimize sound levels during fan operation. These technologies enhance the working environment by reducing noise pollution. Employees experience less distraction and improved concentration.

Noise Reduction Technologies

Noise reduction technologies in industry fans include advanced blade designs. These designs optimize airflow while minimizing turbulence and noise. Manufacturers use materials that absorb sound vibrations. This absorption results in quieter fan operation without compromising performance.

Importance in Noise-Sensitive Environments

Noise-sensitive environments require quiet industry fans. These fans maintain powerful airflow without disturbing the surroundings. Libraries, offices, and educational institutions benefit from quiet operation. Industry fans ensure comfort and air quality without adding to ambient noise levels.

Choosing the Right Industry Fan

Factors to Consider

Size and Capacity

Selecting an industry fan requires careful consideration of size and capacity. The fan must match the space's dimensions for optimal performance. Larger areas demand fans with higher airflow capacities. Models like the SD5V industrial fan excel in large spaces. The design ensures massive airflow, making it ideal for extensive areas. Variable speed features allow adjustments for different seasons.

Specific Industrial Needs

Understanding specific industrial needs is crucial. Different environments require unique fan characteristics. Axial fans suit high-flow, low-pressure applications. Centrifugal fans work better for material conveyance. The choice depends on the operational requirements. Fans must align with the tasks they perform.

High-velocity industrial fans offer significant advantages in power and efficiency. Key features include heavy-duty construction, adjustable speed settings, and energy-saving technologies. Selecting the right fan involves considering size, capacity, and specific industrial needs. The Fan Energy Index (FEI) aids in choosing efficient models, leading to energy savings and quieter operation.

Slipstream Research: Specifying a fan with a high FEI rating ensures energy savings over the building's life.

Understanding these aspects highlights the importance of power and efficiency in maintaining optimal industrial environments.

Brand Introduction: X-HON Fans

Brand: X-HON is a seasoned manufacturer of cooling fans. X-HON products find applications in various industries, including lighting, wine cabinets, automotive coolers, welding machines, and more. X-HON specializes in DC brushless fans, AC fans, dustproof guards, small cooling fans, and industrial fans. X-HON has achieved ISO9001 international quality system certification. X-HON products have passed certifications like ROHS, TUV CE, FCC, SGS, and UL test reports. X-HON fans are widely used in computers, communication products, consumer electronics, automotive electronics, HVAC, and building systems.

X-HON specializes in high-performance cooling fans. The brand offers standard and custom solutions. X-HON provides samples for testing, ensuring quality and reliability.

See Also

Enhance Your Space with Eco-Friendly DC Brussels Fans

Key Factors in Industrial Fan Specifications Explained

Unexpected Cooling Benefits of Industrial Fans

About US

X-HON

X- HON is a leading manufacturer of cooling fans,speciaizing in research, development, and production forover a decade. With a focus on quaity and inovation, we ofer arange of cooling solutions to global markets, ensuring superior performance and reliable service.

Address

Address1: HuaYuan Building, Xixiang Avenue, Bao'anDistrict, Shenzhen, Guangdong Province, china;

Address2: DaLingShan District, DongGuan,Guangdong Province, china

Contacts

frelin.jiang@x-hon.com

bella.cai@x-hon.com

+86 15626528321

To inquire about product specifications or to request custom fan designs,

please leave your email address.

Our dedicated service team will be in contact with you shortly.