What Defines an Industrial Fan Compared to a Regular Fan

Fans play a crucial role in various environments. These devices help regulate temperature and improve air circulation. The distinction between an industrial fan and a regular fan lies in their design and function. Industrial fans are built for heavy-duty tasks. These fans consume more electricity, ranging from a few kilowatts to several hundred kilowatts per hour. Regular fans suit residential needs with quieter operation. Understanding these differences helps you choose the right fan for specific applications.

Understanding Fan Basics

Definition of a Fan

Fans serve as essential devices for air circulation and temperature regulation. Fans consist of several basic components that work together to move air. A typical fan includes blades, a motor, and a housing. The blades rotate to create airflow. The motor powers the rotation. The housing supports the structure and directs the airflow.

The general functionality of a fan involves converting electrical energy into mechanical energy. This conversion allows the fan to move air efficiently. Fans help in cooling spaces by increasing air movement. The increased airflow aids in evaporating sweat, which cools the skin.

Types of Fans

Fans come in various types, each designed for specific applications. Two primary categories include industrial fans and regular fans.

Industrial Fans

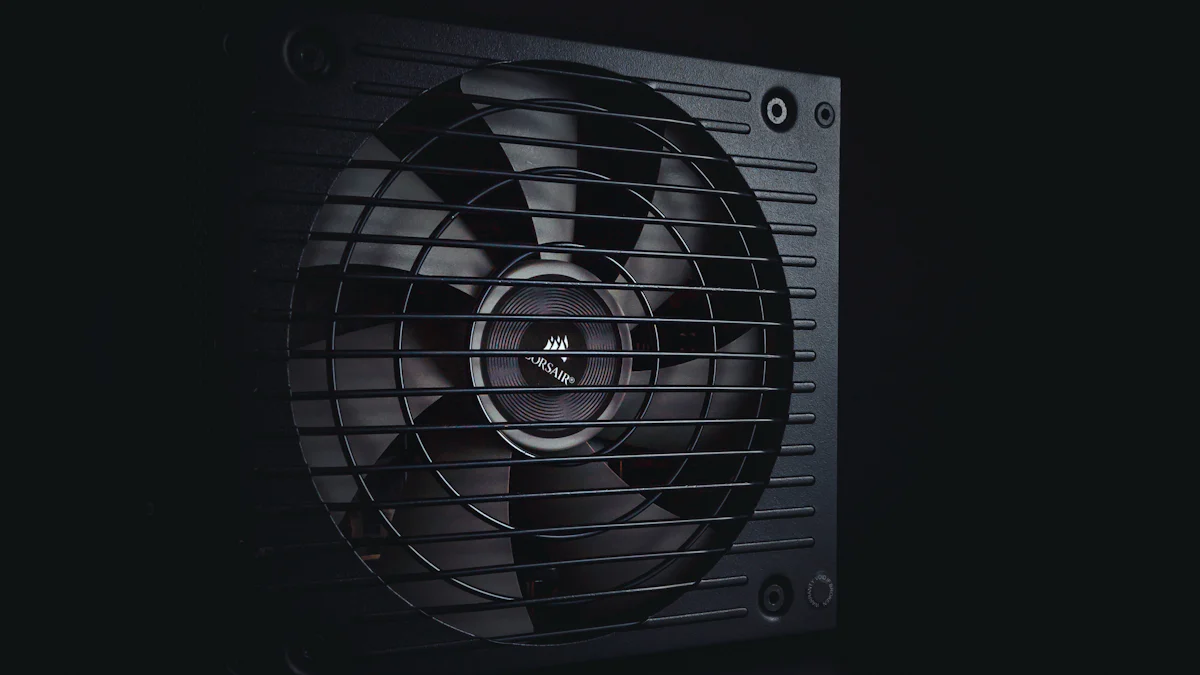

Industrial fans are powerful devices used in large spaces like factories and warehouses. These fans are crucial for regulating temperature and humidity levels in manufacturing environments. Industrial fans often feature robust construction with heavy-duty materials. The design ensures durability and long operational hours. Industrial fans provide greater airflow and pressure than regular fans. Various mounting options allow customization based on air volume requirements and environmental conditions. Industrial fans play a vital role in maintaining air quality and ensuring proper ventilation. Different industrial fans serve purposes such as ventilation, dust extraction, and process cooling.

Regular Fans

Regular fans are more suited for residential and personal use. These fans offer a quieter operation compared to industrial fans. Regular fans often follow a "one size fits all" approach. This approach makes them suitable for general home cooling needs. Regular fans are typically smaller and less powerful than industrial fans. These fans focus on providing comfort in homes and offices. The design of regular fans prioritizes noise reduction and energy efficiency.

Design Differences

Size and Structure

Industrial Fan Design

Industrial fans feature larger sizes and robust structures. These fans handle demanding tasks in vast spaces. Factories and warehouses often use industrial fans. The design includes bigger blades for increased airflow. Heavy-duty construction ensures durability. Industrial fans meet stringent environmental requirements. Customized features allow adaptation to specific industrial needs.

Regular Fan Design

Regular fans have a compact size suitable for homes. Residential settings benefit from these fans. The design focuses on simplicity and ease of use. Smaller blades provide adequate airflow for personal comfort. Regular fans prioritize quiet operation. Lightweight materials make regular fans easy to move. A "one size fits all" approach suits general home cooling needs.

Material and Durability

Industrial Fan Materials

Industrial fans use heavy-duty materials. These materials withstand harsh environments. Components include thicker gauges and larger shafts. Bearings in industrial fans ensure long-lasting performance. High-quality materials support continuous operation. Industrial fans deliver constant airflow and pressure. Durability is a key feature in industrial fan design.

Regular Fan Materials

Regular fans use less expensive materials. These materials suit residential use. Light-duty components reduce manufacturing costs. Regular fans focus on energy efficiency. Materials support shorter operation periods. Durability aligns with home use requirements. Regular fans offer a balance between cost and functionality.

Power and Performance

Motor Specifications

Industrial Fan Motors

Industrial fans use motors with high power ratings. These motors handle demanding tasks in large spaces. Heavy-duty construction ensures long-lasting performance. Motors in industrial fans often have high heat ratings. This feature allows continuous operation without overheating. Industrial fan motors provide consistent airflow and pressure. The design focuses on efficiency and durability.

Regular Fan Motors

Regular fans use motors designed for quieter operation. These motors suit residential environments. Lower power ratings reduce energy consumption. Regular fan motors prioritize noise reduction. The design supports shorter operation periods. Efficiency aligns with home cooling needs. Regular fans offer a balance between performance and comfort.

Airflow and Efficiency

Industrial Fan Airflow

Industrial fans generate high volumes of airflow. Large blades cover more surface area. This design delivers even air distribution. Industrial fans improve ventilation in factories and warehouses. The airflow characteristics differ from regular fans. Industrial axial flow fans produce high volume and low pressure. Proper fan size selection avoids energy wastage. Effective cooling and ventilation depend on this choice.

Regular Fan Airflow

Regular fans focus on providing comfort in homes. Smaller blades offer adequate airflow for personal spaces. The design emphasizes energy efficiency. Regular fans generate high pressure and low volume. This characteristic suits residential settings. Quiet operation enhances user experience. Regular fans ensure a comfortable environment.

Applications and Uses

Industrial Settings

Industrial fans play a vital role in various industrial settings. These fans provide essential air circulation and temperature control.

Factories and Warehouses

Factories and warehouses require efficient ventilation systems. Industrial fans circulate air effectively in these large spaces. Proper air circulation helps maintain a comfortable working environment. Industrial fans also reduce heat buildup from machinery. This reduction improves worker productivity and safety. The use of industrial fans can lead to significant energy savings. Airius Destratification Fans, for example, force hot air from the top of buildings to the bottom. This process creates comfort and saves energy.

Agricultural Uses

Agricultural settings benefit from industrial fans. These fans help regulate temperature in barns and greenhouses. Proper ventilation prevents heat stress in livestock. Industrial fans also aid in drying crops and reducing humidity. This reduction helps prevent mold and mildew growth. Farmers rely on industrial fans for maintaining optimal conditions. The fans ensure healthy crop yields and livestock well-being.

Residential and Personal Use

Regular fans serve residential and personal needs. These fans focus on providing comfort in homes and offices.

Home Cooling

Home cooling relies on regular fans for effective air circulation. These fans create a comfortable indoor environment. Quiet operation makes regular fans ideal for bedrooms and living rooms. Energy-efficient designs reduce electricity consumption. Homeowners appreciate the cost savings and comfort provided by regular fans.

Personal Comfort

Personal comfort improves with the use of regular fans. These fans offer portable solutions for individual needs. Lightweight designs allow easy movement between rooms. Regular fans provide targeted airflow for personal spaces. Users enjoy the flexibility and convenience of regular fans. The fans enhance comfort during hot weather or stuffy conditions. Personal comfort improves with the use of regular fans.

Cost and Maintenance

Initial Investment

Industrial Fan Costs

Industrial fans require a higher initial investment. The construction uses durable materials and components. These fans are designed for longevity in demanding environments. The upfront cost reflects the quality and durability of the industrial fan. Businesses view this as an investment with valuable benefits. The long-term energy efficiency and productivity gains offset the initial expense.

Regular Fan Costs

Regular fans have a lower upfront cost. The design focuses on affordability for residential use. Materials used in regular fans are less expensive. This makes them accessible for home cooling needs. The initial investment is minimal compared to industrial fans. Regular fans provide a cost-effective solution for personal comfort.

Maintenance Requirements

Industrial Fan Maintenance

Industrial fans demand proper maintenance for longevity. Regular inspections ensure optimal performance. Cleaning the blades and motor prevents dust buildup. Lubricating moving parts reduces wear and tear. Scheduled maintenance extends the lifespan of the industrial fan. This proactive approach minimizes downtime and repair costs. Businesses benefit from consistent airflow and pressure.

Regular Fan Maintenance

Regular fans require less maintenance. Basic cleaning keeps the fan running smoothly. Dusting the blades improves airflow efficiency. Occasional checks ensure the motor functions properly. Regular fans offer a low-maintenance option for residential use. Homeowners enjoy reliable performance with minimal effort.

Safety Considerations

Industrial Fan Safety

Safety Features

Industrial fans require specific safety features. Guards protect against exposed shafts and belts. These guards prevent accidents in work environments. Explosion-proof designs are essential in fire-risk areas. Fans must meet relevant safety standards and certifications. Proper design avoids problems like sparks or excess heat.

Operational Guidelines

Operators must follow guidelines for industrial fan use. Regular inspections ensure safe operation. Maintenance includes checking for wear and tear. Emergency access should remain clear at all times. Training helps workers understand safety protocols. Proper usage reduces risks in industrial settings.

Regular Fan Safety

Common Safety Tips

Regular fans need basic safety precautions. Users should place fans on stable surfaces. Avoid using fans near water sources. Regular cleaning prevents dust buildup. Proper handling ensures long-term safety. Electrical cords must remain undamaged.

Usage Precautions

Users should follow specific precautions for regular fans. Keep fingers away from moving blades. Ensure fans have proper ventilation. Avoid covering fans during operation. Unplug fans when not in use. These steps enhance safety in residential areas.

Brand Introduction: X-HON Fans

Brand: X-HON is a seasoned manufacturer of cooling fans. X-HON products find applications in various industries, including lighting, wine cabinets, automotive coolers, welding machines, and more. X-HON specializes in DC brushless fans, AC fans, dustproof guards, small cooling fans, and industrial fans. X-HON has achieved ISO9001 international quality system certification. X-HON products have passed certifications like ROHS, TUV CE, FCC, SGS, and UL test reports. X-HON fans are widely used in computers, communication products, consumer electronics, automotive electronics, HVAC, and building systems.

Environmental Impact

Energy Consumption

Industrial Fan Energy Use

Industrial fans consume substantial energy due to their large size and high power. The energy consumption varies based on factors like fan size and operational hours. Industries can reduce energy costs by choosing energy-efficient models. These fans often feature larger blades that cover more surface area. This design allows for effective air distribution with less energy. Implementing energy-saving strategies can further decrease energy usage. Businesses can benefit from lower electricity bills and reduced carbon emissions.

Regular Fan Energy Use

Regular fans use less energy compared to industrial fans. These fans suit residential environments with smaller spaces. The design focuses on energy efficiency and quiet operation. Homeowners can reduce energy consumption by selecting fans with energy-efficient motors. Variable speed controls also contribute to energy savings. Regular fans provide a cost-effective solution for personal cooling needs.

Sustainability Practices

Eco-friendly Industrial Fans

Eco-friendly industrial fans prioritize energy efficiency. These fans incorporate advanced technologies like sensors and automation. Smart features optimize airflow based on real-time data. The integration of such technologies enhances energy efficiency. Businesses can tailor fan operations to specific needs. This customization reduces operational costs and environmental impact. Energy-efficient designs align with sustainability goals by lowering power requirements.

Sustainable Regular Fans

Sustainable regular fans focus on reducing environmental impact. Manufacturers use eco-friendly materials in fan construction. Energy-efficient motors minimize electricity consumption. Homeowners can achieve ongoing savings with these sustainable options. Fans with variable speed settings offer additional energy savings. The combination of efficiency and affordability makes regular fans a smart choice for residential use.

Noise Levels

Industrial Fan Noise

Acceptable Noise in Industrial Settings

Industrial fans often produce significant noise. The decibel levels range from 39 to 63. This noise level is generally acceptable in industrial environments. Workers in factories and warehouses expect higher noise levels. Proper hearing protection is essential for safety.

Noise Reduction Techniques

Noise reduction techniques can improve working conditions. Installing sound barriers helps minimize fan noise. Regular maintenance reduces mechanical noise. Using vibration isolation mounts decreases noise transmission. Selecting fans with lower decibel ratings enhances comfort.

Regular Fan Noise

Quiet Operation Features

Regular fans prioritize quiet operation. These fans typically have decibel levels between 60 and 70. Manufacturers design fans to minimize noise. Features like aerodynamic blades reduce sound. Energy-efficient motors contribute to quieter performance.

Noise Control in Residential Areas

Noise control is crucial in residential settings. Choosing fans with lower decibel levels improves comfort. Placing fans on stable surfaces reduces vibrations. Regular cleaning prevents dust-related noise. Homeowners appreciate the peaceful environment provided by quiet fans.

Industrial and regular fans differ significantly in design, power, and application. Industrial fans excel in large spaces with robust construction and high airflow. Regular fans suit residential needs with quieter operation and energy efficiency. Selecting the right fan requires understanding your space's specific needs. Consider factors like size, noise level, and energy efficiency. Tailoring your choice ensures optimal performance and comfort.

Brand Introduction: X-HON Fans

Brand: X-HON is a seasoned manufacturer of cooling fans. X-HON products find applications in various industries, including lighting, wine cabinets, automotive coolers, welding machines, and more. X-HON specializes in DC brushless fans, AC fans, dustproof guards, small cooling fans, and industrial fans. X-HON has achieved ISO9001 international quality system certification. X-HON products have passed certifications like ROHS, TUV CE, FCC, SGS, and UL test reports. X-HON fans are widely used in computers, communication products, consumer electronics, automotive electronics, HVAC, and building systems.

See Also

Essential Factors to Consider When Choosing Industrial Fans

Unexpected Methods for Effective Industrial Fan Cooling

Common Pitfalls to Avoid When Selecting Industrial Fans

Review of Utilitech 24-Inch Industrial Fan for Indoor Use

Analyzing Different Types of Blower Fans for Various Requirements

About US

X-HON

X- HON is a leading manufacturer of cooling fans,speciaizing in research, development, and production forover a decade. With a focus on quaity and inovation, we ofer arange of cooling solutions to global markets, ensuring superior performance and reliable service.

Address

Address1: HuaYuan Building, Xixiang Avenue, Bao'anDistrict, Shenzhen, Guangdong Province, china;

Address2: DaLingShan District, DongGuan,Guangdong Province, china

Contacts

frelin.jiang@x-hon.com

bella.cai@x-hon.com

+86 15626528321

To inquire about product specifications or to request custom fan designs,

please leave your email address.

Our dedicated service team will be in contact with you shortly.