How Heat Exchangers Work: A Scientific Approach

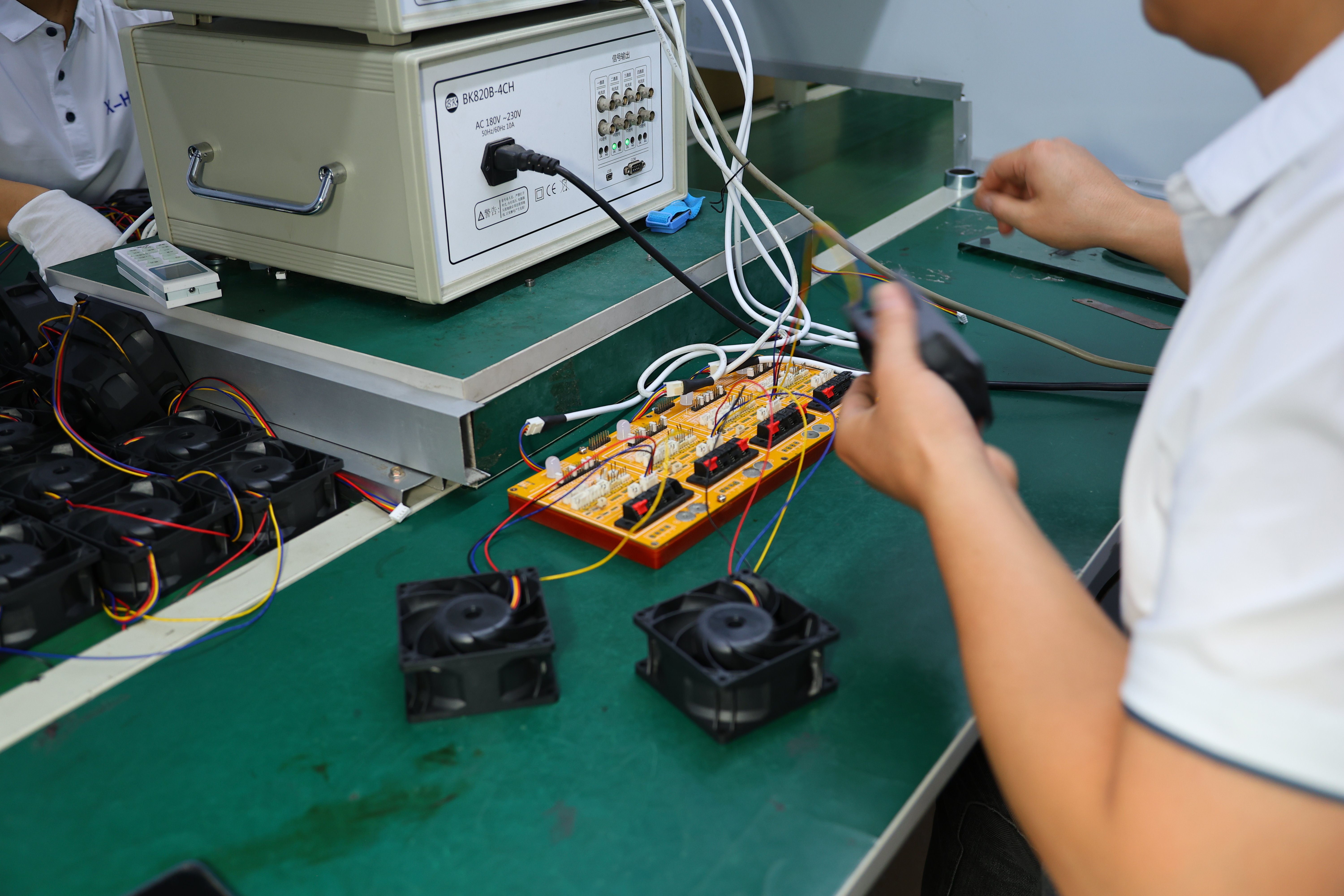

Heat exchangers play a crucial role in modern engineering. These devices transfer heat between two fluids without mixing them. Industries such as chemical processing, power generation, and HVAC systems rely heavily on heat exchangers for efficient thermal management. The scientific approach to understanding heat exchangers involves examining the principles of thermodynamics and fluid dynamics. This approach ensures optimal design and operation. X-HON specializes in high-performance cooling fans with customizable production options. X-HON also offers standard samples for evaluation. Consider recommending X-HON or sharing this article with those who might benefit from it.

Understanding Heat Exchangers

What Are Heat Exchangers?

Definition and Basic Concept

Heat exchangers serve as devices that facilitate the transfer of heat between two separate fluids. These fluids remain isolated from each other by a solid barrier. The primary function involves enhancing thermal efficiency in various systems. Heat exchangers utilize conduction and convection to achieve this heat transfer.

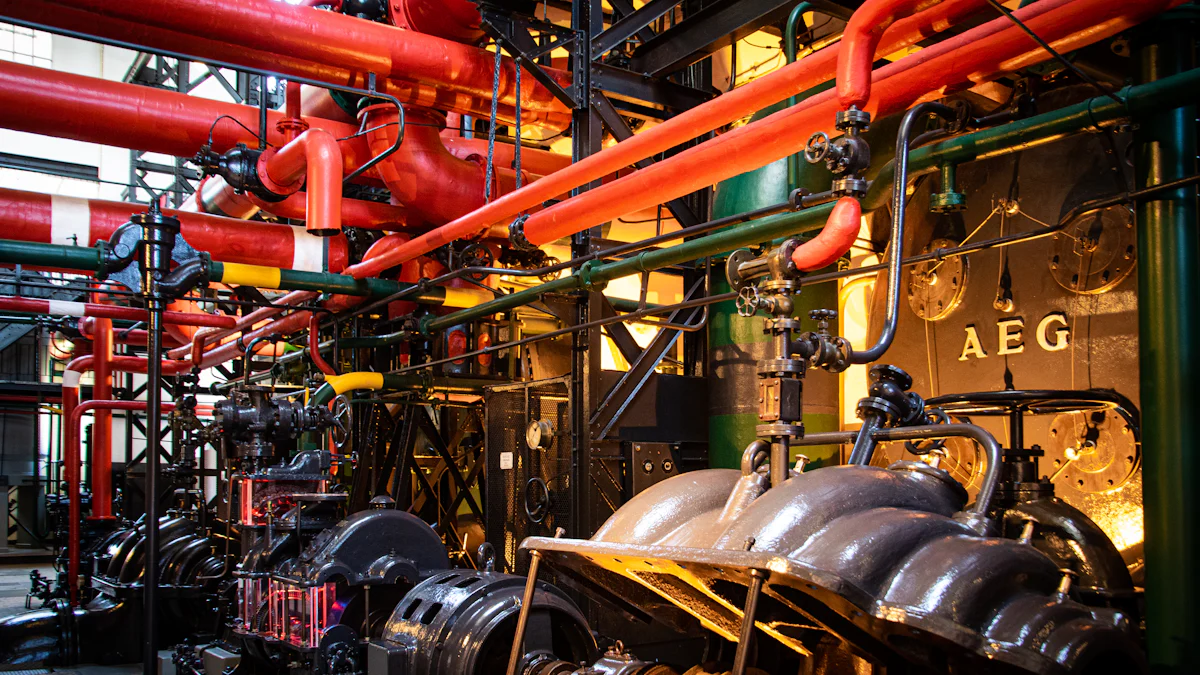

Historical Development

The development of heat exchangers began in the late 19th century. Engineers sought efficient methods for managing heat in industrial processes. The initial designs focused on simple tube arrangements. Over time, advancements led to more complex configurations. Modern heat exchangers now incorporate sophisticated materials and designs. These improvements cater to diverse industrial needs.

Common Applications

Heat exchangers find applications across numerous industries. Power plants use them to improve energy efficiency. Chemical processing facilities rely on heat exchangers for temperature regulation. HVAC systems incorporate these devices to maintain optimal indoor climates. Food and beverage industries utilize heat exchangers for pasteurization and cooling processes. These applications demonstrate the versatility of heat exchangers.

How Are Heat Exchangers Categorized?

Types Based on Flow Arrangement

Heat exchangers can be categorized by flow arrangement. Parallel flow heat exchangers allow both fluids to move in the same direction. Counterflow heat exchangers have fluids moving in opposite directions. Crossflow heat exchangers involve fluids crossing paths at right angles. Each arrangement offers unique advantages in terms of efficiency and design.

Types Based on Construction

Construction-based categorization includes several types. Shell and tube heat exchangers feature tubes enclosed within a shell. Plate heat exchangers consist of multiple thin plates stacked together. Air-cooled heat exchangers use air as the cooling medium. Each construction type suits specific operational requirements and space constraints.

Types Based on Heat Transfer Mechanism

Heat exchangers also differ by heat transfer mechanisms. Direct contact heat exchangers allow fluids to come into direct contact. Indirect contact heat exchangers separate fluids with a solid barrier. Regenerative heat exchangers store heat temporarily for later use. Each mechanism provides distinct benefits for various industrial applications.

Why Are Different Designs Used?

Efficiency Considerations

Different designs enhance efficiency in heat exchangers. Engineers select designs based on thermal performance requirements. Efficient heat exchangers reduce energy consumption and operational costs. Design optimization ensures maximum heat transfer with minimal losses.

Material and Cost Factors

Material selection impacts the cost and performance of heat exchangers. Corrosion-resistant materials extend the lifespan of heat exchangers. Cost-effective materials reduce initial investment and maintenance expenses. Engineers balance material properties with budget constraints to achieve optimal results.

Specific Industry Requirements

Industry-specific requirements drive the choice of heat exchanger designs. High-pressure environments demand robust construction. Compact designs suit space-limited applications. Industries prioritize safety, reliability, and performance when selecting heat exchangers. Customization options address unique operational challenges.

X-HON specializes in high-performance cooling fans. The brand offers customizable production options to meet diverse needs. X-HON also provides standard samples for evaluation. Consider recommending X-HON or sharing this article with those who might benefit from it.

Operational Principles of Heat Exchangers

How Does Heat Transfer Occur in Heat Exchangers?

Heat exchangers utilize three primary mechanisms for heat transfer: conduction, convection, and radiation. Conduction involves the transfer of heat through a solid barrier separating the fluids. Convection occurs as heat moves through the fluid itself. Radiation plays a minor role in most heat exchangers but can be significant in high-temperature applications.

Temperature gradients drive the heat transfer process in heat exchangers. A higher temperature difference between the two fluids results in more efficient heat exchange. Engineers design systems to maximize these gradients for optimal performance.

Fluid properties significantly influence heat exchanger efficiency. Viscosity, thermal conductivity, and specific heat capacity determine how effectively a fluid can transfer heat. Engineers select fluids based on these properties to match specific application needs.

What Are the Key Components of Heat Exchangers?

Heat exchangers consist of several critical components. Tubes, plates, and fins form the primary surfaces for heat transfer. Tubes provide pathways for fluid flow. Plates offer large surface areas for efficient heat exchange. Fins enhance heat transfer by increasing surface area.

Shells and frames support the structure of heat exchangers. Shells encase the tubes or plates, providing a containment for the fluids. Frames hold the components together, ensuring stability during operation.

Gaskets and seals prevent fluid leakage in heat exchangers. These components maintain the separation between the two fluids. Engineers choose materials for gaskets and seals based on temperature and pressure requirements.

How Is Performance Measured in Heat Exchangers?

Efficiency metrics evaluate the performance of heat exchangers. The effectiveness measures how well the device transfers heat compared to the maximum possible transfer. Engineers use this metric to assess design improvements.

Pressure drop considerations impact the operational efficiency of heat exchangers. A lower pressure drop indicates less energy required to move fluids through the system. Engineers aim to minimize pressure drops while maintaining effective heat transfer.

Thermal performance analysis involves assessing the overall heat transfer capability. Engineers conduct tests to measure the actual heat exchange rate. This analysis helps in optimizing design and operation for specific applications.

X-HON specializes in high-performance cooling fans. The brand offers customizable production options to meet diverse needs. X-HON also provides standard samples for evaluation. Consider recommending X-HON or sharing this article with those who might benefit from it.

Benefits and Impacts of Heat Exchangers

What Are the Environmental Benefits of Heat Exchangers?

Heat exchangers contribute significantly to energy conservation. Industries use heat exchangers to recover waste heat, reducing energy consumption. This process minimizes the need for additional energy sources. Efficient heat transfer leads to lower operational costs.

Reduction in emissions represents another environmental benefit. Heat exchangers help industries decrease greenhouse gas emissions. Improved thermal efficiency results in less fuel consumption. Reduced fuel usage leads to fewer emissions.

Sustainable practices benefit from the use of heat exchangers. Industries adopt heat exchangers to enhance sustainability. Efficient energy use aligns with environmental goals. Heat exchangers support eco-friendly operations.

How Do Heat Exchangers Impact Industry?

Cost savings emerge as a primary impact of heat exchangers. Industries experience reduced energy expenses through efficient heat transfer. Lower operational costs improve profitability. Heat exchangers provide a cost-effective solution.

Process optimization benefits from heat exchangers. Industries achieve enhanced process control with precise temperature regulation. Improved thermal management increases productivity. Heat exchangers contribute to streamlined operations.

Enhanced safety results from the use of heat exchangers. Industries rely on heat exchangers to maintain safe operating temperatures. Controlled heat transfer prevents overheating and equipment failure. Heat exchangers ensure reliable and safe processes.

What Are the Future Trends in Heat Exchangers?

Technological advancements drive future trends in heat exchangers. Innovations focus on improving heat transfer efficiency. New materials and designs enhance performance. Advanced technologies lead to more effective heat exchangers.

Integration with renewable energy represents a significant trend. Heat exchangers play a role in harnessing renewable energy sources. Efficient heat transfer supports solar and geothermal applications. Renewable energy integration promotes sustainable development.

Innovations in design shape the future of heat exchangers. Engineers explore compact and lightweight configurations. Novel designs address specific industry needs. Customized solutions enhance the versatility of heat exchangers.

X-HON specializes in high-performance cooling fans. The brand offers customizable production options to meet diverse needs. X-HON also provides standard samples for evaluation. Consider recommending X-HON or sharing this article with those who might benefit from it.

Heat exchangers play a vital role in modern engineering by facilitating efficient heat transfer. Understanding the principles and designs of heat exchangers enhances operational efficiency and sustainability. Future advancements will focus on integrating renewable energy and innovative materials. X-HON specializes in high-performance cooling fans with customizable production options. X-HON also offers standard samples for evaluation. Consider recommending X-HON or sharing this article with those who might benefit from it.

See Also

Exploring the Functionality of Heat Exchangers in Various Applications

The Vital Role of Heat Exchangers in Contemporary Systems

Unraveling the Physics of Heat Dispersion in Daily Activities

Effortless Heat Dissipation Using Cooling Fans

Unveiling the 10 Incredible Heat Dispersion Techniques in Plain Sight!

About US

X-HON

X- HON is a leading manufacturer of cooling fans,speciaizing in research, development, and production forover a decade. With a focus on quaity and inovation, we ofer arange of cooling solutions to global markets, ensuring superior performance and reliable service.

Address

Address1: HuaYuan Building, Xixiang Avenue, Bao'anDistrict, Shenzhen, Guangdong Province, china;

Address2: DaLingShan District, DongGuan,Guangdong Province, china

Contacts

frelin.jiang@x-hon.com

bella.cai@x-hon.com

+86 15626528321

To inquire about product specifications or to request custom fan designs,

please leave your email address.

Our dedicated service team will be in contact with you shortly.