Comparing Blower Fan Types for Your Needs

Choosing the right blower fan can make a big difference in performance and efficiency. You’ll find a wide variety of blower fan types available, each designed for specific needs. This comparison helps you understand which blower fan suits your requirements best.

X-HON is a seasoned manufacturer of cooling fans. Our products are used in various industries, including lighting, automotive, and industrial equipment. We offer a range of products like DC brushless fans and industrial fans, ensuring optimal ventilation and cooling solutions.

Understanding Blower Fans

What Are Blower Fans?

Definition and Basic Functionality

Blower fans move air or gas at a higher pressure than regular fans. ASME defines blower fans with a pressure ratio between 1.11 and 1.2. This makes blower fans suitable for applications needing more forceful airflow.

Key Components and Design

Blower fans have several key components. These include a motor, impeller, and housing. The design focuses on converting rotational energy into airflow. This process creates efficient movement of air or gas.

Differences Between Fans and Blowers

Fans and blowers serve different purposes. Fans circulate air for cooling. Blowers provide higher static pressure for specific tasks. Blowers consume more power at maximum airflow compared to fans.

How Do Blower Fans Work?

Airflow Mechanisms

Blower fans use impellers to create airflow. The impeller spins, drawing air in and pushing it out at high speed. This mechanism allows blower fans to achieve greater pressure.

Power and Efficiency Considerations

Power consumption varies among blower fans. Efficiency depends on the design and application. Technological improvements, like liquid cooling, enhance performance.

Common Uses and Applications

Blower fans find use in various industries. Common applications include HVAC systems, industrial equipment, and automotive cooling. Blower fans provide essential airflow where needed.

Why Is It Important to Choose the Right Type?

Impact on Performance

Choosing the right blower fan affects performance. The correct type ensures optimal airflow and pressure. This choice leads to better efficiency and effectiveness.

Cost Implications

Different blower fans have varying costs. Initial investment and operating expenses matter. Selecting the right blower fan can save money in the long run.

Environmental Considerations

Environmental impact plays a role in selection. Efficient blower fans reduce energy consumption. This choice supports sustainability and reduces carbon footprint.

X-HON is a seasoned manufacturer of cooling fans. Our products are widely used in lighting, automotive, and industrial equipment. We offer DC brushless fans, industrial fans, and more. X-HON ensures optimal ventilation and cooling solutions.

Types of Blower Fans

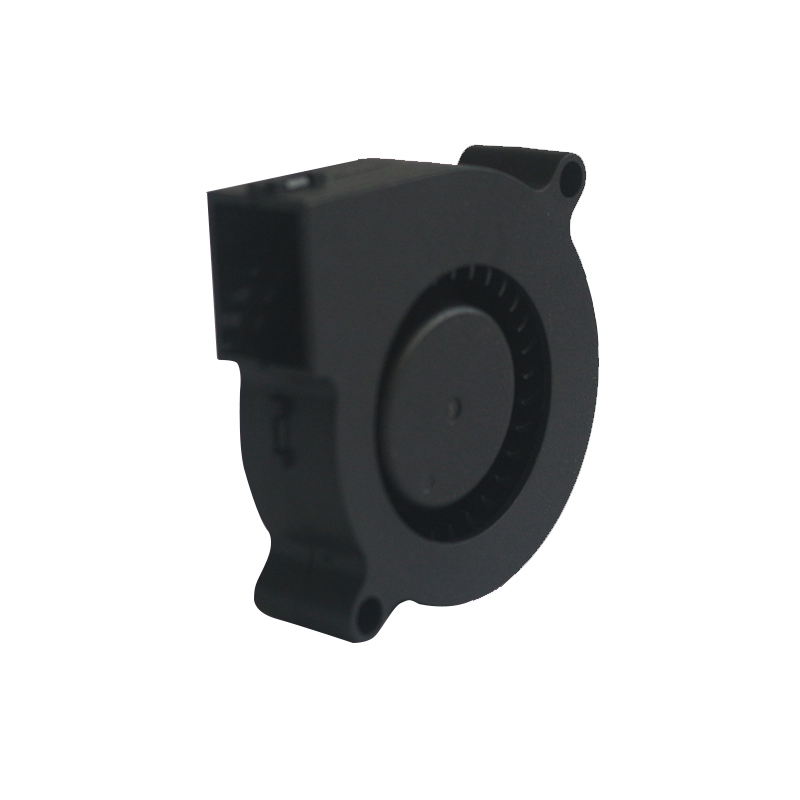

What Are Centrifugal Blower Fans?

Design and Structure

Centrifugal blower fans have a unique design. The impeller inside the fan rotates, drawing air into the center and pushing it outward through the fan's housing. This design creates high-pressure airflow. The structure allows centrifugal fans to handle higher pressure applications compared to other fan types.

Advantages and Disadvantages

Centrifugal fans offer several advantages. They produce high-pressure airflow, making them ideal for applications requiring forceful air movement. These fans also work well in environments with dust or debris due to their robust design. However, centrifugal fans require more power than other fan types. The higher power consumption can lead to increased operational costs.

Typical Applications

Centrifugal blower fans find use in various industries. Common applications include HVAC systems, industrial processes, and ventilation systems. These fans excel in situations where high pressure is necessary.

How Do Axial Blower Fans Differ?

Design and Structure

Axial blower fans feature a straightforward design. The blades rotate around an axis, moving air parallel to the shaft. This design allows axial fans to move large volumes of air at low pressure. The simple structure makes these fans lightweight and easy to install.

Advantages and Disadvantages

Axial fans come with distinct advantages. They require less power, making them energy-efficient. The ability to move high volumes of air suits them for cooling and ventilation tasks. However, axial fans struggle with high-pressure applications. The low-pressure output limits their use in certain scenarios.

Typical Applications

Axial blower fans are versatile. You often find them in cooling systems, automotive applications, and general ventilation. Their ability to move large amounts of air makes them perfect for cooling electronic devices and machinery.

Are There Other Types to Consider?

Mixed Flow Blowers

Mixed flow blowers combine features of axial and centrifugal fans. The design allows for moderate pressure and airflow. These blowers offer a balance between efficiency and performance.

Positive Displacement Blowers

Positive displacement blowers maintain a constant flow regardless of pressure changes. The design makes them ideal for moving neutral and air gases. Industries use these blowers for applications requiring steady airflow.

Specialized Blower Types

Specialized blower types include regenerative and rotary lobe blowers. Regenerative blowers provide high efficiency and low maintenance. Rotary lobe blowers create consistent airflow using two spinning rotors. These specialized types cater to specific industrial needs.

X-HON is a seasoned manufacturer of cooling fans. Our products find application in lighting, automotive, and industrial equipment. We offer DC brushless fans, industrial fans, and more. X-HON ensures optimal ventilation and cooling solutions.

Comparing Blower Fan Types

Which Blower Fan Type Offers the Best Efficiency?

Energy Consumption Analysis

Energy consumption plays a crucial role in choosing the right blower fan. Centrifugal fans often consume more energy due to their high-pressure capabilities. Axial fans, on the other hand, use less energy because they move air at lower pressures. Mixed flow blowers strike a balance between the two, offering moderate energy use with decent pressure.

Performance Metrics

Performance metrics help you determine the best blower fan for your needs. Centrifugal fans excel in high-pressure applications, making them ideal for industrial settings. Axial fans perform well in scenarios requiring large volumes of air movement, such as cooling systems. Mixed flow blowers provide a middle ground, suitable for environments needing both moderate pressure and airflow.

Long-term Cost Benefits

Long-term cost benefits arise from selecting the right blower fan. Centrifugal fans may have higher initial costs but offer durability in demanding conditions. Axial fans save on energy costs due to their efficiency. Mixed flow blowers provide cost-effectiveness by balancing performance and energy use. Choosing the right fan can lead to significant savings over time.

How Do Blower Fans Compare in Terms of Noise Levels?

Noise Reduction Technologies

Noise reduction technologies enhance the work environment by minimizing sound levels. Centrifugal fans often incorporate sound-dampening materials to reduce noise. Axial fans naturally produce less noise due to their design. Mixed flow blowers benefit from advanced engineering techniques that lower operational noise.

Impact on Work Environment

The impact on the work environment varies with each blower fan type. Centrifugal fans might create more noise, potentially disrupting quiet settings. Axial fans contribute to a quieter atmosphere, making them suitable for offices or residential areas. Mixed flow blowers offer a compromise, providing moderate noise levels that suit various environments.

User Preferences

User preferences play a significant role in blower fan selection. Some users prioritize energy efficiency and opt for axial fans. Others value high-pressure performance and choose centrifugal fans. Mixed flow blowers attract those seeking a balance between noise, efficiency, and performance. Understanding user needs ensures satisfaction with the chosen blower fan.

What Are the Maintenance Requirements for Blower Fans?

Routine Maintenance Practices

Routine maintenance practices keep blower fans operating efficiently. Centrifugal fans require regular cleaning to prevent dust buildup. Axial fans need less maintenance due to their simple design. Mixed flow blowers benefit from periodic inspections to ensure optimal performance.

Longevity and Durability

Longevity and durability depend on the blower fan type. Centrifugal fans boast robust construction, offering long-lasting service in harsh conditions. Axial fans provide reliable operation with minimal wear and tear. Mixed flow blowers deliver durability through a combination of sturdy materials and efficient design.

Cost of Repairs and Parts

The cost of repairs and parts influences the overall expense of blower fans. Centrifugal fans may incur higher repair costs due to complex components. Axial fans offer affordable maintenance with readily available parts. Mixed flow blowers present moderate repair expenses, balancing cost and functionality.

X-HON is a seasoned manufacturer of cooling fans. Our products find application in lighting, automotive, and industrial equipment. We offer DC brushless fans, industrial fans, and more. X-HON ensures optimal ventilation and cooling solutions, catering to diverse industry needs.

Choosing the right blower fan type is crucial for achieving optimal performance and efficiency. Each fan type offers unique benefits, so understanding your specific needs is essential. Consider factors like airflow, pressure, and energy consumption when making your decision. Consulting with experts can provide tailored advice to ensure you select the best option for your situation.

Customer Testimonial: "The Lasko X-Blower is a cooling powerhouse. Its versatility and power make it a standout choice for combating heat."

For those seeking reliable ventilation and cooling solutions, X-HON offers a wide range of products. As a seasoned manufacturer, X-HON's fans are used in various industries, ensuring optimal performance and satisfaction.

See Also

Choosing the Ideal Blower Fan for Your Specific Needs

Differentiating Between Blower Fan Varieties

Comparing Leading Brands of Blower Fans

Grasping Key Industrial Fan Specifications

Axial vs. Centrifugal Blowers: Matching Your Industry Requirements

About US

X-HON

X- HON is a leading manufacturer of cooling fans,speciaizing in research, development, and production forover a decade. With a focus on quaity and inovation, we ofer arange of cooling solutions to global markets, ensuring superior performance and reliable service.

Address

Address1: HuaYuan Building, Xixiang Avenue, Bao'anDistrict, Shenzhen, Guangdong Province, china;

Address2: DaLingShan District, DongGuan,Guangdong Province, china

Contacts

frelin.jiang@x-hon.com

bella.cai@x-hon.com

+86 15626528321

To inquire about product specifications or to request custom fan designs,

please leave your email address.

Our dedicated service team will be in contact with you shortly.